Because of their unique stature, it is imperative to use the utmost care when handling them. Miniature bearings must be well cared for, lubricated, and stored under cleanroom conditions to prevent debris from touching them. Their fragile, tiny size is so transparent that even a fine strand of hair could cause damage to the balls and raceways.

Small and miniature bearings are usually sealed with rubber seals and shields to prevent possible lubricant leakages or dust entry.

- Seals and shields for contamination protection

- High tolerance levels to exact application requirements

- Performance testing for friction and noise

- Rigorous factory lubrication from a stock of several lubricants

- Extended flanged outer rings and inner rings for mounting capabilities

- Contact angle and radial play variations to enable different deflection requirements and application loading [source]

Access to the most miniature bearings to meet your specific project will eliminate long lead times, defeat supply chain bottlenecks, and satisfy customer demands.

At Bearing & Drive Systems, you get the bearings you need according to your requirements without hassle. Our lubrication services and "Clean Room," which is critical to the miniature bearing, help you meet any customer's specifications.

If you're interested in miniature bearings, we discuss what they are and how they can meet your precision requirements.

Keep reading...

Miniature Bearings: What are They and How They Meet Your Precision Requirements

Miniature ball bearings are small bearings with balls as their rolling element. They are sometimes called instrument bearings or micro bearings with outer and inner rings, retainers, snap rings, and balls.

This bearing comes in different types and designs to meet the most precision instrument application requirements. This bearing type includes high-speed radial, full ball complement, radial retainer, angular contract, thrust, and pivot.

Miniature bearings are produced under the standard European metric sizes under 20 mm, varying from ⅛ of an inch in overall diameter to 20mm in overall length. They come in inch and metric sizes. Manufacturers make the exact sizes, each with their variants on ABEC ratings and custom modification sizes.

The ABEC rating system uses odd numbers—1, 3, 5, 7, 9—as classification ratings. The five distinct classifications are arranged in ascending order of tolerance. A higher rating signifies tighter tolerances, higher precision, efficiency, and speed capabilities for the bearing. [source]

Typical miniature ball bearing bore sizes start at 1 mm and have an outside diameter of 10 mm, with the smallest bearing bore size being .0400 and an overall diameter of 1/8th to 12 inches. Because of its unique size, this bearing is helpful in many applications.

Design Attributes: What are the Most Important Requirements of a Miniature Bearing?

With miniatures, important attributes are speed, accuracy, and longevity. In addition, the quietness of the bearing running at high speeds can also be imperative.

They provide reliable, high performance for moderate radial and thrust loads at low operating torque.

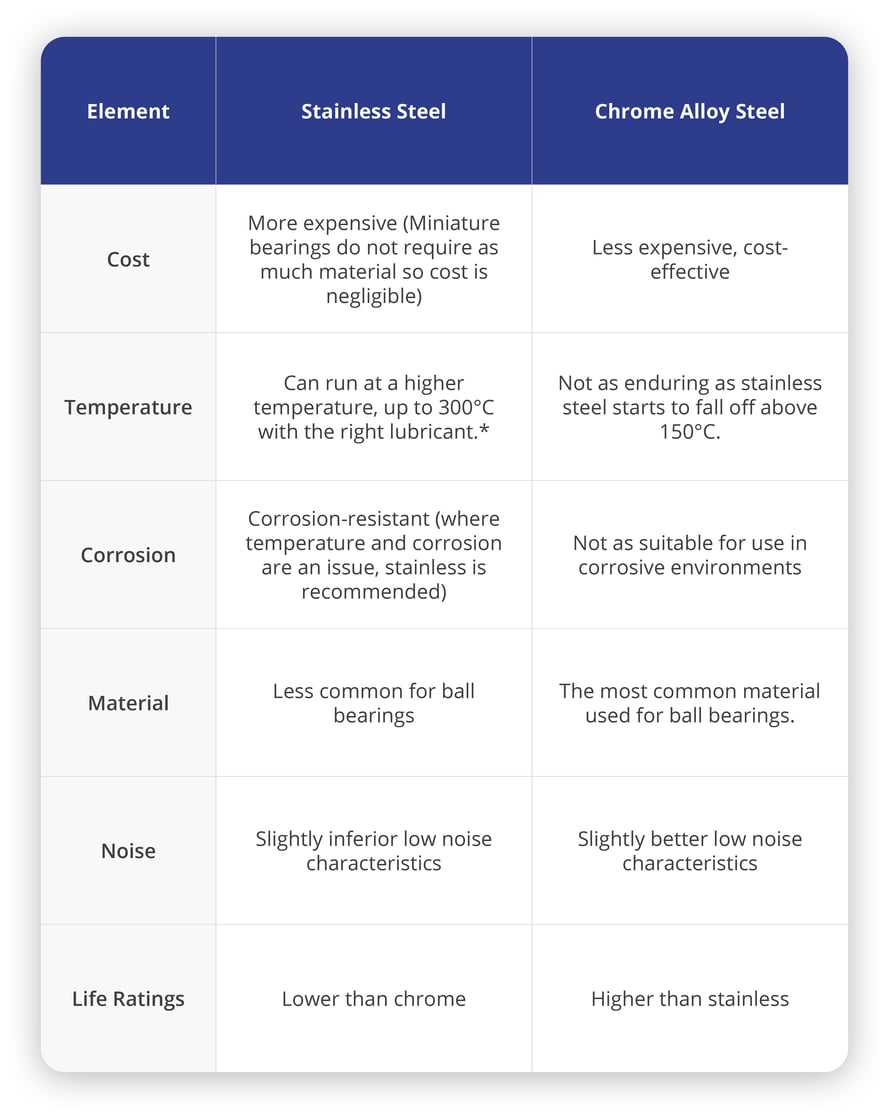

The most common material for ball bearings is chrome steel because it offers high load capacity and low noise properties. Miniature/instrument bearings are not used in high load applications, and because of the small amount of material used, stainless steel is used to make many of the bearings.

Where temperature and corrosion are an issue, stainless steel is recommended. There is a high risk of corrosion in damp environments with chrome steel bearings. source.

Stainless and chrome steel offer users a high strength-to-wear ratio, essential for long service life and efficient operation.

Let's look at the differences/similarities between stainless steel and chrome alloy steel...

Comparison of Stainless Steel vs. Chrome Alloy Steel Bearings

* As lubrication experts trusted by major manufacturers, we know finding the correct grease for your bearing application can be a struggle. With our 30+ years of experience and knowledge, we can take some of those burdens and be your "go-to" for lubricant optimization. We at BDS can offer miniature bearings with customer-specified oil or grease lubricants.

Because we extend the life of your bearings enormously, we put together an in-depth guide. We will discuss the different types of lubricants, the best methods for bearing lubrication, proper procedure for applications, and mistakes you might have made to ensure the long service life of your bearings.

Miniature bearings can be offered with customer-specified oil or grease lubricants.

Miniature Bearing Applications

When choosing a ball bearing for a specific application, you must take various factors into account:

- Speed

- Load conditions

- Size availability

- Accessibility requirements.

Miniature bearings are used for extremely high speeds. These bearings offer low noise, vibration, and frictional torque performance.

They are used in medical, instrumentation, and semiconductor equipment, specialized aviation market, dentistry, avionics, instrumentation, robotics, computers...the list goes on.

"One trend gaining traction in this market is the rise of the industrial robotics market. Rising adoption of miniature ball bearings for articulated robotic arms requiring high-precision is likely to foster the growth of the market in the long run." [source]

The pandemic has also influenced the rise in competition in the miniature ball-bearing market.

“As more organizations focus on specialized consumer bases, the Miniature Ball Bearings market is becoming increasingly competitive. Since the beginning of the pandemic, most companies have chosen different techniques for regional market conditions to recover from the pandemic. For example, most European customers continue to emphasize brands with a strong purpose and high values. In contrast, in several Asia Pacific economies, there has been a fundamental change away from critical items. The report analyzes the company activities, SWOT analysis, and economic profile of Miniature Ball Bearings Industry.” [source.]

Challenges of Miniaturization of Bearings

Miniature bearings are highly engineered components that lower friction and enhance the equipment's operational life.

The global miniature ball bearings market is forecast to grow at a CAGR of 7.62% from 2018-2022.

However, growth is not without its challenges.

Maintenance and flexibility can become challenges if you do not pay attention to these areas with their small size.

Regular maintenance should become a top priority to maintain a smooth operation and long life. Lubrication plays a critical role in maintaining the bearings.

Excessive force during assembly is probably the most common cause of raceway damage in miniature bearings. Such damage contributes to elevated torque and noise levels and short life. The usual suspects are that improper handling and interference from poor design or tolerance stack up. [source]

Small bearing options may be hard to find and make it challenging to complete a working project. Working with a supplier with the needed options can eliminate the challenge.

Conclusion

The global Miniature Ball Bearings market Growth is anticipated to rise considerably during the forecast period, between 2022 and 2029. In 2022, the market was growing steadily, and with key players' increasing adoption of strategies, the market is expected to rise over the projected horizon." [source]As a leading distributor of miniature bearings, BDS offers a wide range of options for your customers across various industries. We offer both stainless steel and chrome alloy steel miniature bearings.

We know it's stressful going outside your typical supply chain to find the correct bearing for your customer, and ordering globally can be daunting.

Our global sourcing network at BDS enables you to get the bearing you need according to your order requirements without hassle. Contact a bearings expert today.