The BDS Difference

Week Turnaround

Weeks Saved

Senergy Industrial Solutions needed new 10" ID Bearings quickly after a failure ended up shutting down their plant.

.jpeg)

Motion Industries needed 6PCS. of part number M28344DW/410D/410/410 for a customer.

Motion Industries needed to locate a Timken M283449DW 900024 bearing for a customer's reversing mill.

A customer reached out looking for help locating a TORRINGTON B9362G triple ring bearing that was used at a Georgia Pacific paper mill in a deflection compensation roll.

A major distributor needed to locate a Timken/Torrington 287TQO816 bearing for a customer's reversing mill.

No immediate stock at branch. Customer needed part with special grease.

No stock at factory or branches. BDS had the cups and cones in stock, and was able to send the parts over to BMC in order to have a spacer made and ground to the correct end play to compose the requested.

No stock at factory or branches. BDS had stock on the part with steel balls. Utilizing our sister company, BMC

Spoke with Michelle regarding stock that they would like to have re-lubricated, and Updated cure dates.

Applied had a paper mill customer that needed a spherical bearing with special clearance asap. BDS has part in stock and shipped out same day order was received. SKF 23156 CAC C4 W33. BDS extensive stock allowed the customer to get the bearing they needed quickly as opposed to waiting 4-6 weeks.

.jpg)

Applied needed a discontinued Timken double cone. Timken has not produced this HM252343D in many years. BDS had stock that has been well preserved. BDS inspected and warrantied the product and shipped same day order was received.

.jpg)

Customer needed 5405 with a bronze retainer. 5405 is a fairly common size but no one makes them with the bronze retainer anymore. BDS still has stock that has been kept correctly over the years. Able to ship out same day.

M241547/M241510 After hours order. Sat afternoon customers plant was completely down and they needed parts asap. BDS had cups and cones in stock and had ready for a same day courier to pick up within 2 hours. Parts were taken directly to customer in Alabama who was able to get up and running Sunday morning instead of waiting to place a order on Monday and waiting to get the parts from there.

BDS had a job from a restoration foundation that restores old WW2 aircraft. In this particular instance, they had a job to restore a WW2 PBY Catalina for a museum. This Catalina was actually on a mission out of Iceland and was sunken by a German U boat in WW2. BDS was able to provide all the old and obsolete bearings needed to rebuild and restore this amazing aircraft. As well as retain a piece of valuable history that could have been lost forever.

Week Turnaround

Weeks Saved

BDS Rebuild Lead Time:

2 Weeks

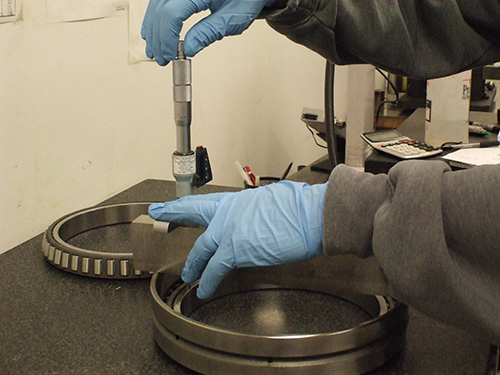

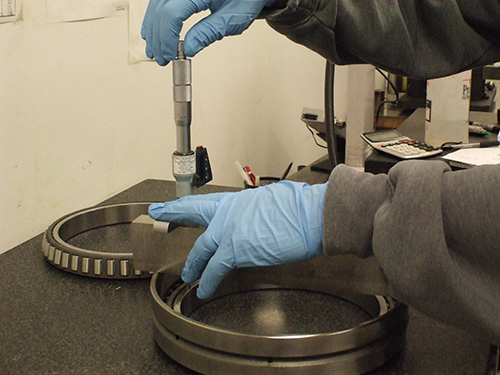

Senergy Industrial Solutions has worked with Bearing & Drive Systems and Bearing Manufacturing Company on several projects. All projects have gone smoothly but the most impressive job involved 2 pinion bearings and 2 special OEM Housings.

These 10” ID bearings failed and the plant had a very short window of time to get them replaced and back in service because our plant shut down. The OEM had a 12-14 week lead time.

The crew at Bearing & Drives and Bearing Manufacturing broke down the failed units and provided the plant with very a detailed failure analysis. After reviewing the data collected and considering the application parameters, several changes were recommended by both the BDS and BMC team.

The following modifications were made in house by BDS and BMC:

All this happened in a 2-week timeframe which was very expedited. The modified and assembled units were couriered to their shop and installed in the required time frame.

"BDS is our go-to bearing repair shop because of their ability to provide extremely valuable technical support coupled with master workmanship," said Mel Young at Senergy Industrial Solutions

Now, the bearings run cooler and smoother than before and the modifications and overall repair jobs were exceptional, according to Young.

Cost Savings

Weeks Saved

.jpeg)

Motion Industries needed 6PCS. of part number M28344DW/410D/410/410 for a customer.

When they reached out to the manufacturer, they learned that the lead time for a new bearing was 28 weeks, which was much longer than the customer had anticipated. Not to mention, the cost of the 6 new pieces from the manufacturer was $727,931.34.

Motion Industries then reached out to BDS to see if they could instead rebuild these bearings. Using the advanced repair capabilities of our sister company BMC, not only were they able to rebuild these 6 pieces and have it to the customer in just 14 weeks, but the rebuilt bearing cost much less at $254,000.00

Besides reducing the downtime by 14 weeks, Motion Industries was able to get their customer the bearing they needed and helped them save $473,931 by working with BDS and BMC.

Cost Savings

Weeks Saved

Motion Industries needed to locate a Timken M283449DW 900024 bearing for a customer's reversing mill.

When reached out to the manufacturer to purchase a new bearing, they learned the lead time for the new bearing was 28 weeks, which was much longer than the customer had anticipated, and the cost of the new was $121,321.89.

Motion Industries then decided to reach out to BDS to locate the bearing. Not only were we able to source a new bearing and get it delivered to the customer in just 1 week, but the cost of the sourced bearing was significantly less at $115,000.

Not only was Motion Industries able to get their customer the bearing they needed to reduce their reversing mill's downtime by 27 weeks, but they also saved them $6,321.89 by working with BDS.

In Stock

Days Delivery Time

A customer reached out looking for help locating a TORRINGTON B9362G triple ring bearing that was used at a Georgia Pacific paper mill in a deflection compensation roll.

The customer's search for this specific triple ring bearing was falling short because it was not in stock anywhere, and as a result, they were feeling pressured on time and the stress that comes with finding a solution.

Since no stock was available anywhere, we worked with the customer to instead use a remanufactured bearing that we had ready to go at our facility in Cleveland, OH.

We shipped the bearing to Valmet (3rd party that rebuilds large rolls for paper mill customers) and the customer got what they needed delivered in 2 days, so they could get back up and running to alleviate extended downtime. Even though the bearing was remanufactured, BDS still honored a year warranty on it (same as buying new).

Cost Savings

Weeks Saved

A major distributor needed to locate a Timken/Torrington 287TQO816 bearing for a customer's reversing mill. They reached out to the manufacturer to purchase a new bearing and the lead time for the new bearing was 28 weeks, which was much longer than the customer had anticipated. The cost of the new bearing from the manufacturer was: $363,965.67

The distributor reached out to BDS to locate the bearing and we were able to source a new bearing and get to the customer in just 1 week. The cost of the sourced bearing was $339,000.00. BDS also authenticated the bearing and guaranteed it with a one year warranty.

By working with BDS, the distributor was able to get their customer the bearing they needed to reduce the downtime of their reversing mill by 27 weeks and save them $24,965.67.

Cost Savings

Cost Savings

No immediate stock at branch. Customer needed part with special grease. BDS had part in stock, and had them flushed and relubricated with Kluber Isoflex 15 grease. We were able to relubricate the bearings to the customer's specifications in our Class 1000 White Room. Once the relube was complete, we shipped direct to the branch for customer pick-up.

Cost Savings

Cost Savings

No stock at factory or branches. BDS had the cups and cones in stock, and was able to send the parts over to BMC in order to have a spacer made and ground to the correct end play to compose the requested

Cost Savings

Cost Savings

No stock at factory or branches. BDS had stock on the part with steel balls. Utilizing our sister company, BMC, we were able to do a changeout to ceramic balls and drop-shipped direct to the customer.

Cost Savings

Cost Savings

Spoke with Michelle regarding stock that they would like to have re-lubricated, and Updated cure dates. First Call sent us a skid of bearings, over 500 pcs, including assemblies. BDS was able to re-inspect, re-lubricate, and re-package within 3 weeks. BDS was able to complete the skid, and renew their stock for an additional 5 years upon date of shipment.

Cost Savings

Cost Savings

Applied had a paper mill customer that needed a spherical bearing with special clearance asap. BDS has part in stock and shipped out same day order was received. SKF 23156 CAC C4 W33. BDS extensive stock allowed the customer to get the bearing they needed quickly as opposed to waiting 4-6 weeks.

Cost Savings

Cost Savings

.jpg)

Applied needed a discontinued Timken double cone. Timken has not produced this HM252343D in many years. BDS had stock that has been well preserved. BDS inspected and warrantied the product and shipped same day order was received.

Cost Savings

Cost Savings

.jpg)

Customer needed 5405 with a bronze retainer. 5405 is a fairly common size but no one makes them with the bronze retainer anymore. BDS still has stock that has been kept correctly over the years. Able to ship out same day.

Cost Savings

Cost Savings

M241547/M241510 After hours order. Sat afternoon customers plant was completely down and they needed parts asap. BDS had cups and cones in stock and had ready for a same day courier to pick up within 2 hours. Parts were taken directly to customer in Alabama who was able to get up and running Sunday morning instead of waiting to place a order on Monday and waiting to get the parts from there.

Cost Savings

Cost Savings

.jpg)

From customer “I have lost count on how many times you have helped me out of vendor no stock situation, or the item is no longer available. In this case the customer needed the bearing in a few days and the factory lead time was months. This bearing will go into a large aluminum extrusion saw. It helped the customer by getting it quickly and not holding up there build schedule.” Part 2mm308WICRDUL

Cost Savings

Cost Savings

BDS had a job from a restoration foundation that restores old WW2 aircraft. In this particular instance, they had a job to restore a WW2 PBY Catalina for a museum. This Catalina was actually on a mission out of Iceland and was sunken by a German U boat in WW2. BDS was able to provide all the old and obsolete bearings needed to rebuild and restore this amazing aircraft. As well as retain a piece of valuable history that could have been lost forever.

14888 Foltz Parkway

Strongsville, Ohio 44149

United States

Phone: 1-800-772-2479